5ml Rispharm LDPE

Product number: 1653

The worldwide reference for patient-friendly premium multi-dose droppers suitable to be used with generic drugs and new formulations.

Specs:

Product Information:

-

Manufacturing TechnologyIBM - Injection Blow Moulding

-

ShapeRound

-

Width21.2 mm

-

Height42.6 mm

-

Weight2.95 g

-

MaterialLDPE, PELD

-

Capacity / Volume5 ml

-

Brimful / Flush Fill Volume7.3 ml

-

Neck Diameter13 mm

-

Neck Finish13 mm

Features & Benefits:

Features

• Bottle & nozzle in white or natural

• # Nozzle drop size

• # Nozzle flow control features

• # Cap colours

• Sterilization G.I and/or ETO

Benefits

• Compatible with Risdrop™ nozzle

• Compatible with Activated Rispharm™

• Combining functionality and aesthetics

Regions Available

- Global

Ideal For:

Ophthalmic Drug delivery

Factory Locations:

Bangalore, India

Pair With:

-

Rispharm & Rispharm R2 Short Closure TE Tamper evident closure compatible with Rispharm And Rispharm R2 sets

View Product -

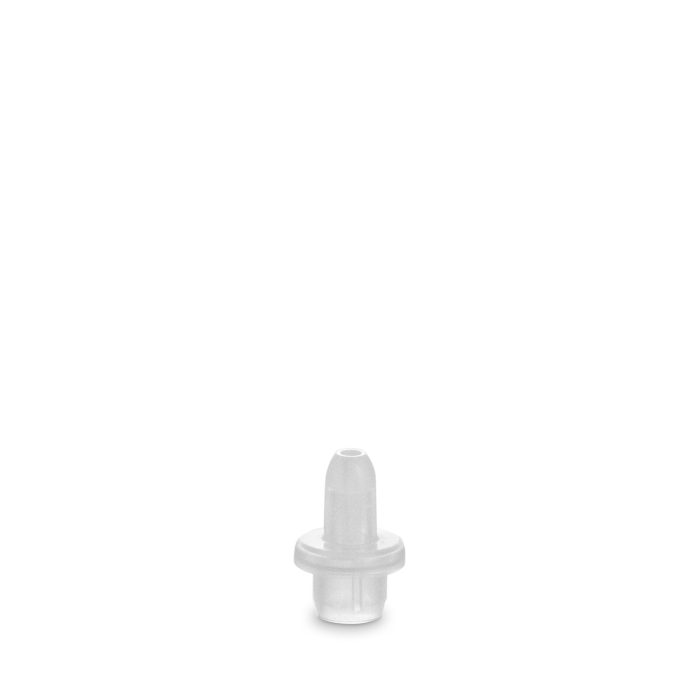

Rispharm Risdrop Nozzle Risdrop Nozzle A unique patented ophthalmic nozzle for a safe and reliable drug delivery with flow control in 30 µL, 45µL, and 60µL. Able to customize size and flow control on request

View Product -

Rispharm Short Child Resistant TE Closure - HDPE Child Resistant and Tamper Evident closure suitable on all Rispharm Range

View Product -

Rispharm & Rispharm R2 Nozzle 45µL Nozzles and Eyedrops compatible with Rispharm & Rispharm R2 bottles and Caps

View Product -

Rispharm & Rispharm R2 Nozzle 30µL Nozzles and Eyedrops with flow control compatible with Rispharm and Rispharm R2 bottles and Caps

View Product -

Rispharm & Rispharm R2 Nozzle 43/58µL Nozzles and Eyedrops with flow control compatible with Rispharm and Rispharm R2 bottles and Caps

View Product -

Rispharm & Rispharm R2 Nozzle 60µL Nozzles and Eyedrops with flow control compatible with Rispharm and Rispharm R2 bottles and Caps

View Product

Recently Viewed

Related Products

Accelerating the possible. Right now.

Berry Global is now Amcor.

Learn More

.png)

10l D-Stacker Range

10l D-Stacker Range

.jpeg)